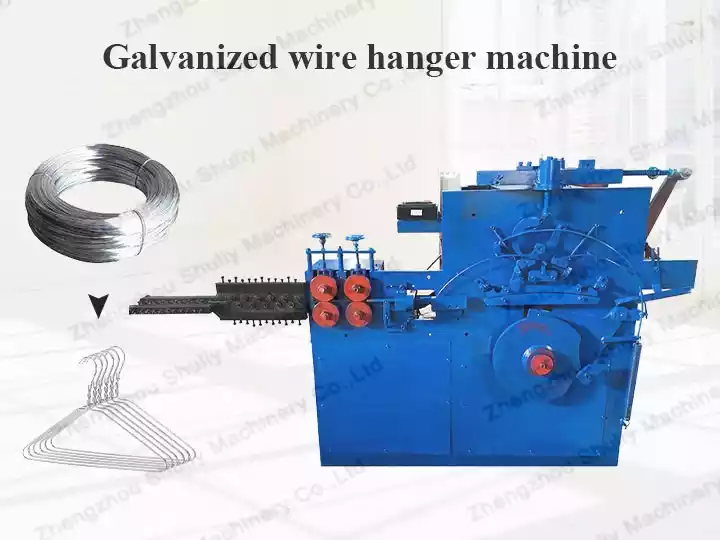

Coat hanger Making Machine | Hanger Production Machine

| Model | SL-40 |

| Capacity | 30-40pcs/minute |

| Voltage | 220V/380V |

| Hanger size | Customize |

| Net weight | 700KG |

| Machine size | 1800*800*1650mm |

| wire diameter | customize |

You can now ask our project managers for technical details

Coat hanger making machine is a machine that uses plastic wire to make a hanger machine. The machine is characterized by high work efficiency, and a high degree of intelligence, and does not require excessive human participation. The coated wire hanger machine has made huge profits for many manufacturers.

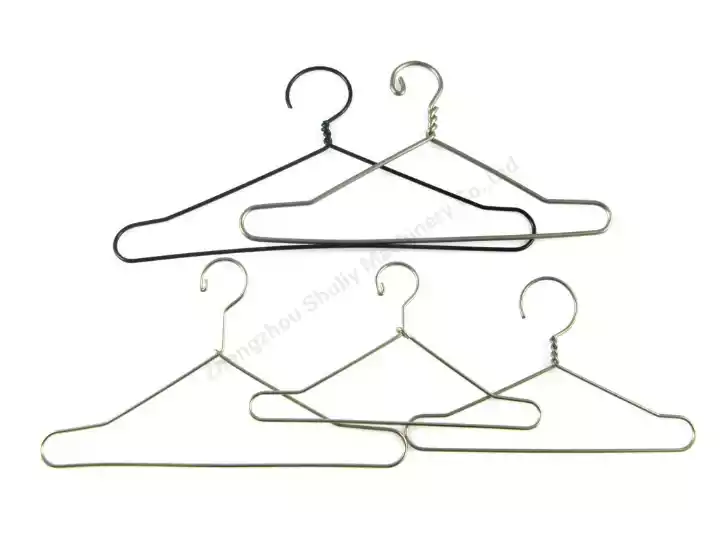

What is plastic coat wire?

Coated wire is processed galvanized wire and iron wire. After passing through the coating machine, the wire will be wrapped by a layer of plastic coat. Such a wire is called a coated wire, and the processed wire is made into a hanger. It is exquisite, and you can choose a variety of colors for the hanger machine to attract customers to buy. In addition, the coat hanger making machine after dipping is more anti-slip. If you use iron wire to produce hangers, it can also play a protective role in drying clothes.

The main advantages of the coat hanger making machine

- The length of the feeding line is standard.

- The speed can be adjusted according to the wire diameter, any speed.

- With high output and fast speed, the fastest can produce 45 pieces per minute.

- The most convenient is to replace the mold (the style of the hanger), which is convenient and simple. Enter the required wire length on the screen and move the position of the cutter.

- The machine can be adapted to produce: 201 stainless steel, 410 stainless iron, electroplating wire, ordinary iron wire, rubber-coated wire, and aluminum wire.

- This coat hanger making machine adopts automatic numerical control, accurate wire feeding, stable operation, and low noise, One machine can produce a variety of hangers. One worker can manage 4-8 machines, which can fully save labor for you. and the applicable wire diameter is 1.7-3.5.

What are the benefits of hanger-coating plastic?

The dipping process has the characteristics of non-toxicity, wear resistance, light resistance, bright color, and good hand feeling. Now, plastic-dipped and plastic-coated products can also be seen a lot in daily life, such as plastic-dipped dumbbells, especially the dumbbells that have been impregnated with hemp surfaces. There are also guardrails. The previous guardrails were easy to fall off the paint, but the guardrails after dipping can be used for several years without fading, and the colors are still as bright as new. After years of experience, the rubber-coated hanger has become a very mature process and is very safe and reliable. Shuliy company has a complete production line of rubber, fully automated production.

Parameters of coat hanger making machine

| Model | SL-40 |

| Capacity | 30-40pcs/minute |

| Wire diameter | Customize |

| Voltage | 220V/380V |

| Hanger size | Customize |

| Net weight | 700KG |

| Machine size | 1800*800*1650mm |

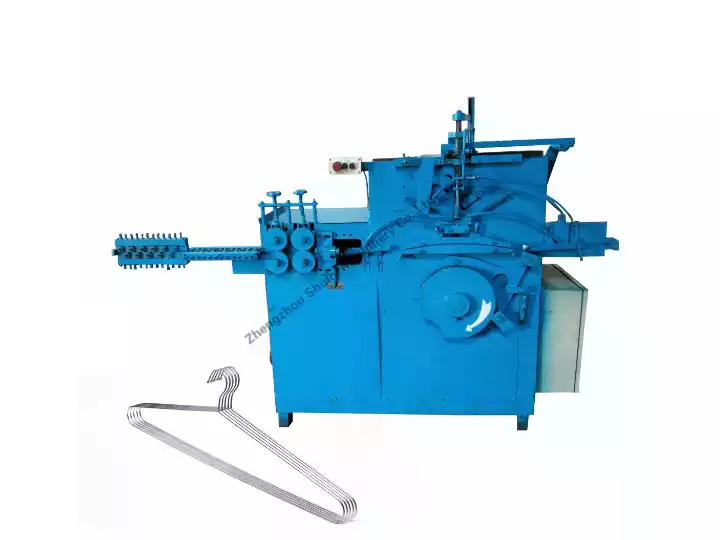

Hanger product machine producing the size of the hanger

The size of the hanger can be made into 16-19 inches. The wire diameter of the raw materials used is generally 1.6-3.8mm. Generally, the larger the diameter of the wire used, the better the support of the hanger and the more durable the hanger. In addition, the mold of the coat hanger making machine can be customized, just send us the picture and size of the hanger, and we will arrange for the designer and factory staff to make the specific mold.

Use of coat hanger maker

When the rubber-coated hanger forming machine is in use when the automatic switch of the thread is turned on, the automatic hanger forming machine will switch the main machine to the manual switch, and then tap the switch to introduce the thread into the tailor knife, when it enters the mold. Observe whether the wire is straightened, In the metal hanger forming machine, the wire must be straightened. Observe the length of the wire, twist the traction handle pressing wheel, the hanger forming machine, the tightening is the length of the wire, the price of the coat hanger making machine, and the loose is the short wire.

Maintenance of coat hanger making machine

The maintenance of the coating hanger forming machine is very important. When the coat hanger making machine is no longer working, the power must be cut off, and the coat hanger making machine is not used under the condition of prohibiting long-term power. When the switch is on, the host is switched to manual, and then the switch is jogged to introduce the thread into the tailor’s knife when it enters the mold. Observe whether the wire is straightened, the wire must be straightened.